Alex Robinson, Irresistible Materials Ltd

10-11am, August 26, 2025 Zoom

The Multi-Trigger Resist

Novel resist materials are required to support the ongoing improvement of EUV lithography. Resolution, roughness and dose requirements will continue to become more severe. In addition, depth of focus will be significantly reduced with the move to High-NA, necessitating reductions of the thickness of both resist and underlayer, and in turn the need for increased EUV photon absorption and etch durability, to enable viable patterning and pattern transfer. Irresistible Materials (IM) is developing novel resists based on the multi-trigger concept. The multi-trigger resists are negative-tone organic molecular materials, based on cationic ring opening polymerization. In a multi-trigger resist (MTR) multiple elements must be simultaneously activated to enable the catalytic reaction. Chemical contrast and resolution are therefore enhanced due to a dose dependent intrinsic quenching behaviour, and MTR shows good lithographic results and wide flexibility. Here we present recent progress with the MTR. Pitch 28 L/S patterning is demonstrated at 50 mJ/cm2, with 105 nm focus margin. Larger pitch L/S patterning with low roughness and a sub-30mJ/cm2 dose, suitable for double patterning applications has been investigated. P32 pillars, with 2.5 nm LCDU, and low dose (<40 mJ/cm2) and p32 contact hole patterning has also been demonstrated.

Emily Gallagher

July 22, 2025

Climate-aware IC Manufacturing

Gila Stein

May 27, 2025

Catalyst Diffusion in Chemically Amplified Resists

Cheng-Hao (Will) Wu

March 25, 2025

Dry deposition and dry development of metal oxide resist and its extendibility to high NA EUV lithography

Douglas Guerrero

Jan 28, 2025

A more sustainable method to disrupt traditional wafer processing in lithography

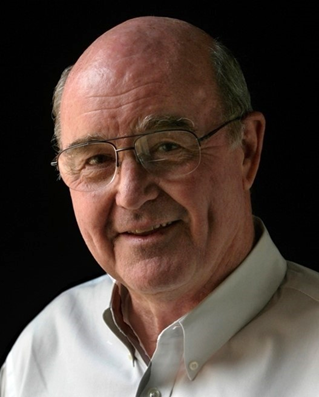

John Petersen

Dec 4, 2024

Probing Extreme Ultraviolet Exposure of Photoresists

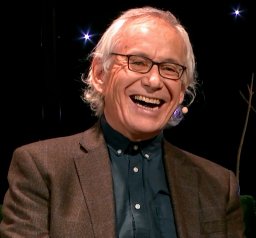

Grant Wilson

September 25, 2024

Materials for High Resolution Imaging Applications

Greg Parsons

August 28, 2024

Inhibitor-Free Area-Selective Deposition via Combined Atomic Layer Deposition and Etching

Daniel Sunday

June 26, 2024

Depth Profiling Structure and Orientation in Confined Soft Matter

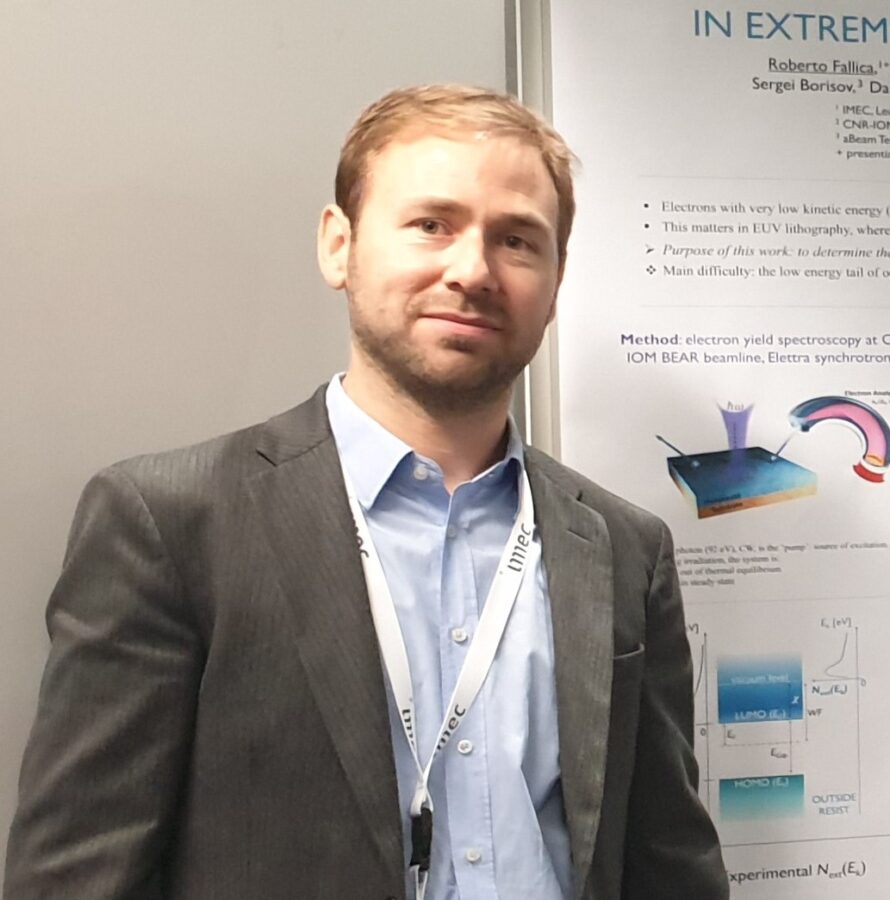

Roberto Fallica

May 22, 2024

Characterization of EUV materials: from well-established to pioneering methods

Patrick Naulleau

April 24, 2024

Benefits and challenges of phase shift mask technologies in the EUV regime

Lander Verstraete

March 27, 2024

Directed Self-Assembly: a Perspective on Line/Space and Contact Hole Patterning for Logic and Memory Applications

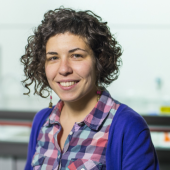

Sonia Castellanos

January 24, 2024

The soft side of metal-oxide resists